The Mechanical Workshop

The mechanical group has several different fields of activity:

Micro wave activities

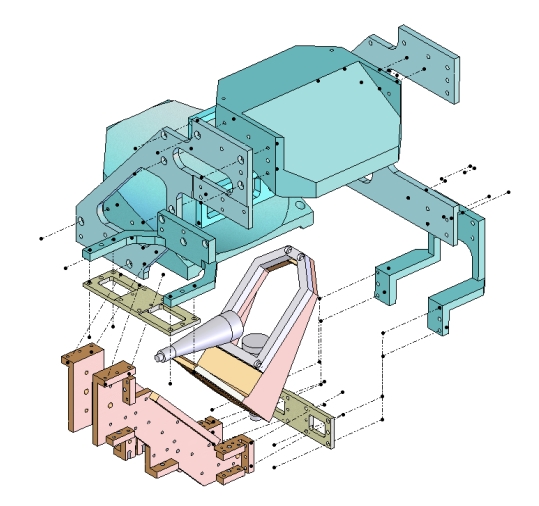

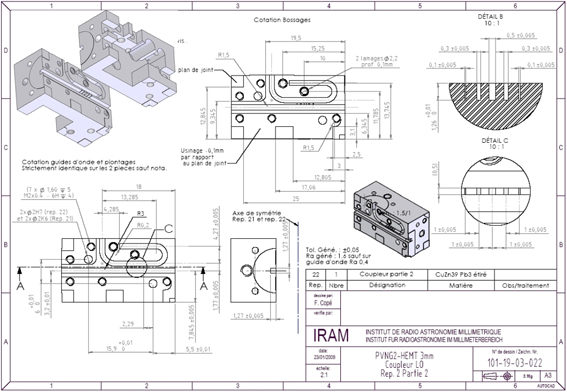

One of the main working fields of the group is the design and manufacturing of mechanical devices for the telescopes’ receiver systems (like mixers, horns and couplers). Several different production steps can be distinguished:

Before starting the manufacturing process, IRAM engineers at the Frontend group determine the so called “ideal signal path” to take for the millimeter signal inside the mechanical devices. The engineers therefore use a special computer aided design software, before drawing the “path” in 3-D.

In a joint effort, the mechanical group and the Frontend group determine the devices' functional necessities and required performances, like the wave-guide’s width, the type of grooving to be used, its tolerated depth, width and localization, the constraints of mass and the limits of tolerance for the actual manufacturing process.

Having completed the technical studies, the mechanical group’s engineers start to design the devices with a special CAD-software, called solid works. In order to guarantee high-precision devices, the design department and the mechanical workshop are closely working together.

|

|

| 3-D drawing of a mixer assembly | Design of a coupler module |

Before the devices are produced, they have to undergo various technical control procedures. IRAM engineers validate their:

- size

- functional performance

- manufacturing precision

- and production costs

Once the validations are finished successfully, the workshop group starts the production. Using micro mechanical manufacturing technologies, the devices are manufactured in the institute’s mechanical workshop, controlled, and finally assembled in the IRAM laboratories.

Activities around the NOEMA Observatory

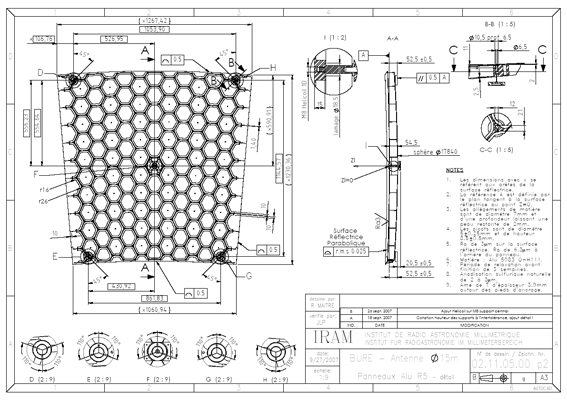

The mechanical group is also partly responsible for the antenna array at the Plateau de Bure. The group is in charge of the design and the construction of the 15-meter antennas. It assists the observatory’s staff during the maintenance period and keeps optimising the antennas’ performance.

An example for the workshop's expertise is the manufacturing of the aluminum panels: The antenna panels are milled by a numerically controlled machine and then stress-relieved in order to obtain a high-precision surface. With their long-time experience, IRAM engineers are able to achieve a surface precision of about 20 μm for 1.5 square meters!

|

|

|

Maintenance phase of the 176 panels of antenna1 |

Design of the antenna panels |

The manufacturing of housings

Another field of activity is the design and the manufacturing of housings for IT modules and electronic chips. Therefore, the mechanical workshop is also equipped with several conventional machines which are not – like all the other machines at the workshop – digitally controllable. The group has its own network of subcontractors for prototypes.

Although this activity is only subsidiary, the mechanical group is able to respond flexible and adapt quickly to those demands.